Common installation mistakes in fire hydrant systems

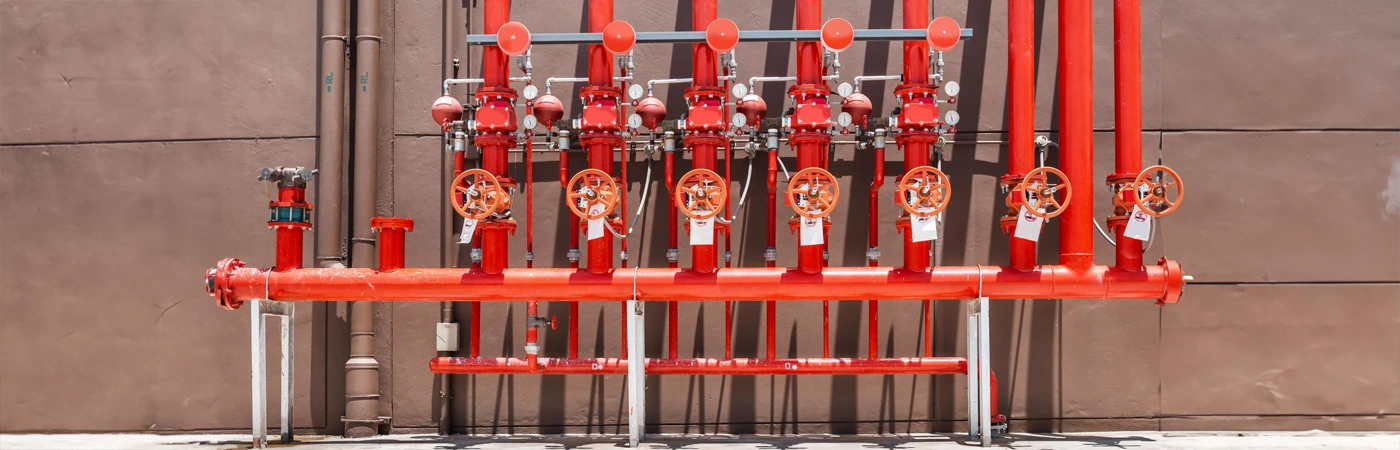

A fire hydrant system is one of the first lines of defence when a fire breaks out. It helps people act fast and gives fire crews the water they need to control the flames. But the system can only do its job when it is installed with care. Small errors during installation can lead to major failures in a real emergency.

At Trident Automation Systems, we often come across issues that could have been avoided with the right planning and workmanship. In this blog, we talk about the common mistakes we see and how you can avoid them.

Mistakes to Avoid When Installing a Fire Hydrant System

Wrong pipe sizing

Many systems fail because the pipes are not sized correctly. If the pipes are too small, the water flow becomes weak. If it is too big, the pressure drops. Both problems reduce the system's strength during a fire.

A proper site study, supported by trained fire engineers, helps select the right pipe size and layout. Our team checks height, water demand, and future load to guide clients towards the right design.

Poor pump selection

A hydrant pump is the heart of the system. When the wrong pump is installed, the system struggles to push enough water during an emergency. Sometimes the pump is too weak, or the pressure is unstable. In some sites, the pump is chosen without checking the building’s real needs.

This makes the whole system unreliable. A detailed pump calculation and brand-tested models help avoid the mistake. Our team uses approved pumps that support long-term performance and easy maintenance.

Incorrect pump room layout

Many installation teams place pumps too close to each other or leave little space for service work. A crowded pump room makes repairs slow and risky. Sometimes, the room does not have enough air ventilation, which leads to overheating.

A well-planned pump room is clean, dry, spacious, and easy to access. It helps the system stay active for years. We design pump rooms that are safe, simple to maintain, and built to meet fire guidelines

Weak water storage planning

Some buildings install a hydrant system without checking if the water tank is big enough. A hydrant system needs a steady and strong water supply during a fire. If the tank is small or not filled properly, the system may run dry when it is needed most.

Another common issue is placing the tank too far or too low, which affects the pressure. We help clients plan the right tank size and location based on building area and fire load.

Improper hose reel and hydrant point placement

Hose reels and hydrant points must be placed where people can reach them quickly. However, in many sites, they are installed in incorrect locations—hidden behind furniture, placed too high or too low, or positioned far from escape routes. These issues delay emergency response during critical moments.

Every hydrant point must be easy to access, clearly marked, and simple to use. Our installation team ensures proper placement by considering real-time fire situations and practical usability at every step.

Loose or weak fittings

A hydrant system is only as reliable as its joints. Loose couplings, weak bolts, and poor sealing can lead to leaks or sudden bursts during operation. These issues reduce water pressure and may cause structural damage.

Using high-quality materials, trained technicians, and properly tested fittings helps eliminate these risks. At Trident Automation Systems, we follow strict quality checks to ensure every joint remains strong even under high pressure.

Poor electrical wiring for pumps

Many fire hydrant pumps fail due to improper electrical wiring. Loose connections, incorrect cable sizes, and unprotected wiring increase the chances of breakdowns. Some pump rooms also lack emergency power backup, causing pumps to stop working if the main power fails during a fire.

Our electrical team installs clean, safe, and well-organized wiring systems with proper markings, ensuring smooth pump performance and reliable operation during emergencies.

Skipping pressure testing

Some installation teams complete the work but skip pressure testing, or perform it incorrectly. Without proper testing, hidden issues like leaks, trapped air, or weak joints remain unnoticed until an emergency occurs.

Pressure testing helps detect problems early and ensures each component functions as expected. We conduct complete and thorough testing before handing over any system to the client.

Improper or weak signage placement

Hydrant systems require clear and visible signage to guide people during emergencies. Many buildings overlook this, resulting in missing or poorly placed signs that make it difficult to locate hose reels, landing valves, or pump switches.

We install bright, durable, and easy-to-understand signs that help people navigate quickly, even in low-light or smoky conditions.

Blocking system access

Some buildings install effective fire hydrant systems but later block access with furniture, storage materials, or construction items. A blocked hydrant point cannot assist during an emergency and slows down the response time.

We educate clients on maintaining clear access around hydrant points and pump rooms throughout the year to ensure quick and unobstructed use in emergencies.

Lack of coordination between teams

A fire hydrant system requires coordination between civil, electrical, plumbing, and safety teams. In many projects, poor communication results in issues such as incorrect pipe routes, blocked shafts, or misaligned pump bases.

Our project managers ensure proper coordination by bringing all teams together, planning the workflow clearly, and monitoring every stage of the installation process.

No regular service after installation

Even a well-installed hydrant system needs regular service to stay effective. Without routine maintenance, pumps may rust, gauges may fail, and pipes can accumulate dirt or blockages.

We provide annual maintenance services that keep the system clean, active, and ready for immediate use at any time.

Conclusion

A good fire hydrant system is more than a requirement; it is a promise of safety. But this promise holds only when the system is installed the right way. Simple mistakes can turn into major risks during an emergency.

With careful planning and proper work, you can avoid these problems and keep your building protected. At Trident Automation Systems, our team supports clients with honest guidance and steady, on-ground expertise.

Looking to install or upgrade your fire hydrant system? Connect with us today, and we'll help you choose the right path for your safety needs.

copyright © Trident Automation Systems Pvt. Ltd. All rights reserved.